What's Better? Screen Printing Or Direct To Garment?

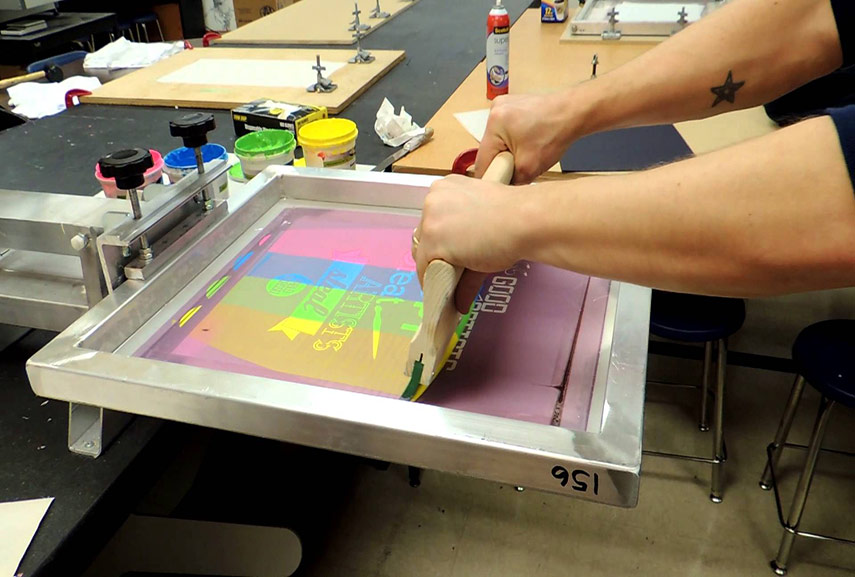

Print suppliers often limit you to not more than 8-9 colours allowed in your custom attire printing. The oldest method of display printing makes use of plastisol, which is the trade commonplace. The means it actually works is a squeegee forces the ink through a mesh stencil and onto the material. Although the machine wants handbook labor to operate it, it is bulletproof! Any breakdowns that do happen are rare and are troublesome to troubleshoot. Most of these machines are well-setup without anticipating issues. DTG printing is a a lot simpler course of than display printing, as every color that is chosen in the design for display printing is printed individually.

To begin with, it’s helpful to have a primary understanding of each kinds of printing. Screen printing is the extra conventional method, and it includes urgent ink through a stencil on a display onto the material. The efficient resolution of display screen printing is very low, so there are solely so many little dots you presumably can put in that in a sure area of print. You have to suit millions of little dots in your design to suit tons of of probably the most. So the reproduction of very exact photographic colours is slightly bit troublesome with display printing. DTG printers use specifically formulated ink that fixes with textiles. Your standard inks out of your printer at house wouldn’t try this so.

If you concentrate on your paper printer at house, a digital printer used for DTG printing is similar factor but for garments! With digital shirt printing the color palette is limitless, which allows you recreate just about something from single colour logos to high-color photographs. You may have a photo printed on a custom-made t shirt and provides it to grandma. Creating personalized single pieces with digital printing has by no means been simpler.

This sort of printing can be increasingly frequent for use in gentle furnishings due to its higher resolution. There’s a cause screen printing has continued to be a successful selection for hundreds of years. Screen-printing also has extra of a human contact to it, thanks to the guide processes included within its creation and the need for that extra little bit of attention to detail. We proudly print utilizing water based mostly inks which are higher for the environment and ship the softest outcomes obtainable, here is why. In phrases of sturdiness, display screen printing certainly wins the battle of the fade, with typically longer lasting outcomes that face up to heavy responsibility washing.

Whichever print method wins the most rounds takes home the championship belt. It should be famous that just because DTG printed shirts value lower than silk screened ones, that doesn’t mean their quality is any much less. The DTG printers we use at One Hour Tees are state-of-the-art and have a very excessive decision. This means all the small print of your design will show up crystal clear and you can select considered one of many various colors.

In display printing and customized attire decoration, you might be more like a barber than a mass producer. You are liable for creating a custom experience that displays the customer's needs. Become the professional and guide your clients toward decorations and customizations that they will love – and that allow you to flip a revenue. Ultimately, there isn't any clear winner between DTG and display screen printing. There are simply too many variables in the custom attire trade to say that one ornament style is thebest oronly way to accomplish the final word objective.

You can get a single t-shirt printed in beneath an hour and have it delivered on the same day. This on-demand functionality is just about inconceivable to search out with display screen printing. As with all printing strategies past and current, there are a couple of limitations with display screen printing. Screen printing is a multi-step course of that is greater than a hundred years old. Simply put, the printing process entails pushing ink by way of a stenciled mesh display screen on to a substrate, which is the t-shirt in our case. Use warmth switch to do orders on your associates while assessing your suitability for the enterprise.

This method is ready to take very intricate, detailed designs and an excellent multitude of colours and apply them with relative ease. Screen printing is cost-effective for bigger runs of less complicated designs with fewer colors. However, this method isn’t as budget-conscious for multiple-color designs, and you'll solely print one design run per set of screens you arrange. Direct-to-garment printing uses biodegradable water-based inks that quickly soak into the fabric. It also makes use of comparatively much less water in comparison with different printing methods, making it a quite extra sustainable method.

DTG printing usually does not supply bulk savings the way that display printing does. But with display printing, there are sometimes cost savings in-built as you print extra t-shirts! Having master stencils for every layer streamlines the process as more shirts are printed. If the shopper wants a high-quantity print with advanced artwork, you do not need to sacrifice quality.

DTG, however, offers you extra freedom to play with colours and complex details. One thing that DTG printing doesn't work nicely with is transparency. If the elements aren't 100% opaque, they don't translate nicely when printing on t-shirts. The printer makes up for the clear design by spreading the ink, making the print look spotty and smudged.

The high quality and the durability are still incredibly good no matter what kind of textile you are using. The display printing approach includes using a woven mesh that helps a stencil that blocks the ink to realize a required image. The stencil creates open areas of the mesh that transfers ink, or another printable merchandise, by pressing the picture onto the substrate.

Lots of decorators offer multiple imprinting options, similar to digital printing and display screen printing. There are definite advantages to each, depending on the sort of artwork you’re utilizing, substrates you’re adorning and portions your buyer needs. When it involves warmth transfer, the strategy is quick and value efficient for printing small orders however then, it’s inefficient for large orders. Screen printing is cost-effective for large orders but ineffective for small orders. DTG gives you the very best quality of graphics however then again, it won’t print on materials apart from cotton. To make the most effective determination for your corporation, understanding all these technical variations between the 2 customized attire printing methods is essential.

We do not offer this service and often have very high minimums in addition to a lengthy turnaround time. The nature of customized t-shirt dropshipping is such that the majority usually, top quality, one-off prints are the secret. Unless there's a requirement to print more than a number of hundred units, DTG will always be the most viable choice for any print on demand business. For these print jobs which might be of upper quantity the place you'll be using the identical design again and again, display screen printing may be a viable option. It is great for bulk orders, permitting you to print numerous the same design somewhat shortly. While several DTG manufacturers declare that they will create a Pantone match, they'll solely use CMYK. Some superior DTG machines have two extra hues; brilliant green and brilliant pink.

This means that the design you create can go onto T-shirts, indicators, business varieties and extra. A DTG printer allows you to render images in high-resolution, high-quality particulars, and you've screen printing ink got got many colour choices. Here’s a quick rundown of when to make use of digital vs. screen printing. Remember, the extra knowledgeable you are, the extra probably your prospects shall be to order from you, on repeat. While not exactly a printing methodology, embroidery can additionally be value wanting into as a t-shirt design component. DTG can even limit the place you place the designs on the t-shirt. Most direct to garment printers do not do sleeve prints and wrap around prints because of the complexity concerned.

The cost per shirt is way decrease than silk screening as a outcome of how shortly shirts could be printed using the DTG methodology. The inks are specially designed to be strong, sturdy, and incredibly vivid in shade. The total time it takes to print one shirt is wherever from five to ten minutes, depending on the complexity of the design and how many colors had been used. Depending on the specifics of your customized printing project, one will doubtless be a higher choice than the opposite. The greatest differences that you should consider when selecting a technique fall into two basic categories — design andcost. Screen printing involves the process of pushing the ink by way of a woven mesh stencil onto the fabric. This is a extra moderen t-shirt printing method that’s gained a lot of popularity in recent times due to technological improvements in DTG printers.

If a picture is photographic or has gradients, display screen printing requires halftone dots. You would possibly remember seeing them if you ever checked out a comic book guide with a magnifying glass.

Welkom bij

Beter HBO

© 2024 Gemaakt door Beter HBO.

Verzorgd door

![]()

Je moet lid zijn van Beter HBO om reacties te kunnen toevoegen!

Wordt lid van Beter HBO