Screen Printing Vs Dtg For T

From raised print to textures to shines and sparkles and glows, there’s a specialty ink or additive that may do it. The best part is you'll have the ability to mix many of these for creations which would possibly be restricted only by your creativeness . Versatility on this context is the flexibility to print on quite lots of textiles, in addition to a wide range of garment types, print locations and placements. If the ink is simply too thick, it can crush the entrance of the shirt, or wherever the print sits. This is especially important for all of the lightweight blends so popular today.

At BYOG, we used both display printing and heat switch to provide our prospects with a broad range of choices for customized t-shirts, bags and even hats. Our Dublin, CA location contains all of the know-how on-site to provide the quality clothing you’re on the lookout for, on the low worth you need. These printers use textile inks that are applied instantly onto the material to create a fully-realized image before your eyes. A display printer will use single permeable screens, on which ink is positioned to be pulled throughout the material in a pattern dictated by the stencil placed on the mesh itself. There is a special technique of vinyl transfer, referred to as fast print or express print, where a design is printed onto heat press vinyl and then applied to a shirt.

The two hottest attire printing strategies are Screen and DTG (direct-to-garment) printing. Once DTG know-how turns into more advanced, and extra ubiquitous, to the purpose the place most people can’t tell the difference, then popularity would possibly not be a factor. DTG, however, crushes it in the consistency department. Because a machine processes a digital file and prints directly onto the shirt, there are virtually no variables to worry about, besides perhaps the location of the garment onto the platen. Much of it is determined by the capabilities of the print store you’re using, however the backside line is that screen printing has fewer restrictions. Most regular screen-printing jobs might be printed with a normal layer of ink, and on dark garments will in all probability be two layers of ink, counting the required underbase. Plastisol tends to be heavy on the shirt, one of the causes it’s so durable.

Because a special screen must be made for every design, there must be a lot of orders for this methodology to be financially feasible. Direct-to-garment, or DTG, is a printing technique that sprays the ink onto the garment using inject know-how. Some printers will ask you to submit print information separates into layers of every colour. They may additionally ask you to specify the colour codes for inks they should use to print your design.

No matter which t-shirt method you select, you will love the outcomes. DTG makes use of water-based inks that are more transparent than plastisol. The DTG ink, subsequently, enables the ink to mix nicely, creating lovely and easy gradients. DTG uses water-based ink that lacks plastisols’ opaque and vibrant nature, especially for clothes with a darker shade. Since this sort of printing is eco-friendly, it's going to make certain that you run a inexperienced firm that helps with promoting in some communities. Because it requires upfront funding and fairly a little bit of your time to get the designs print-ready.

It’s been around for a very long time invented by the Chinese sooner or later in time. As the name suggests a display or stencil is used because the barrier to switch the inks on the specified area of the garment. It all lies with choosing the proper ink for the type of cloth to be printed on. They are more inexpensive then DTG and require much less enter than display printing. This makes them ideally placed for low-cost products, together with mugs, bags, t-shirts, sweatshirts and extra. Direct to garment printing is right for use with heavily-patterned designs and even for the creation of garments in which a large-scale photograph is required. With the right remedy, the inks used for DTG are designed to final in the long-term, providing increased wearability.

With most DTG printers, you can print roughly one shirt every two minutes. They are not maintenance-free machines – and DTG printing is NOT a "push button" printing style. Screen printing is the reasonably priced way to print hundreds of shirts. Screen printing and DTG (direct-to-garment) printing are two of the most typical ways to print customized t-shirts. We are one of many largest manufacturers, importers and wholesalers of blank apparel for adults and youth. Our headquarters is predicated in California and we distribute nationwide.

However, a display screen printer's setup cut-off dates what's possible. But if they should print multiple designs, or do only a few prints, display screen printing can be prohibitively expensive compared to DTG printing. At Spreadshop, there are a number of printing methods that can be used. Instead, you have to take into consideration whether or not you need digital direct printing. However, you can also think about plot printing, whether it is available on your specific design.

For DTG printing, after you might have the machine, you merely input the design and it will print the product. However, that price is offset when you’re making a massive number of the identical print. Because display screen printing is more environment friendly, you’ll save money in the long run printing the identical design on bulk apparel time and again. Your only retail high quality choice, you go into any store and a lot of the t-shirts there might be screen-printed. So as an alternative of display screen printing generally they’re accomplished with digital know-how like a transfer or one thing and applied to the shirts. But the major majority of t-shirts are screen printed that you’d buy from a shop.

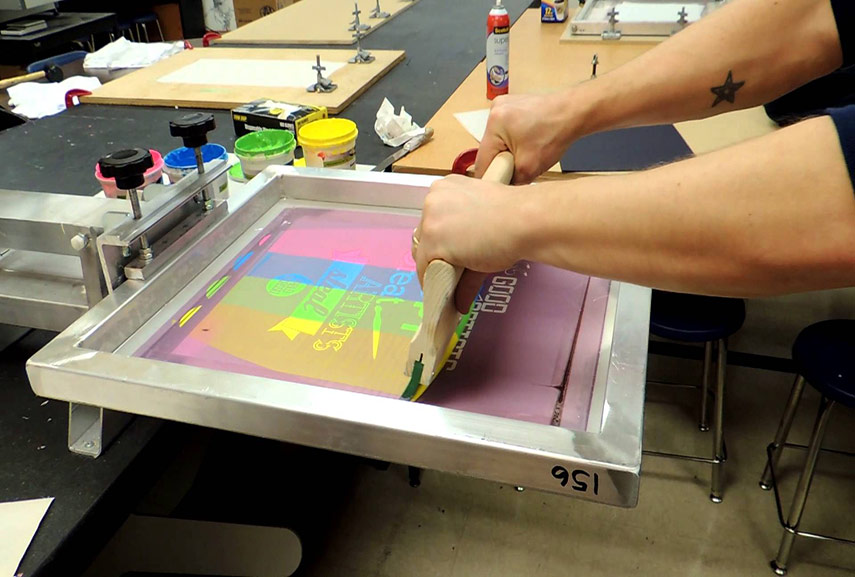

Screens and setup make screen printing too expensive for low-quantity customized orders. DTG printing inks also require curing to completely adhere. Most DTG printing shops use a curing dryer or heat press to treatment their products. The display screen is placed on a screen printing press and registered so it will properly align on the printing floor (typically, a t-shirt). Ink is pressed via the openings in the stencil with a squeegee, directly applying ink onto the printing floor. Digital printing can be utilized on a wider range of apparel and have beautiful results.

Other Asian international locations adapted the methods to their own cloth coloring and modified the technique. Japan experimented with paper minimize out stencils to create imagery that might then be transferred on textiles. In distinction, DTG printers use a kind of know-how that supports high-volume direct-to-garment production even with the most detailed pictures or art work. However, there are some downsides to using display screen printing. Sure, there are colours which may be out-of-gamut speedball screen printing ink for display printing as properly, but overall, its gamut is way bigger than DTG’s. When you absolutely have to match exact colours in your model, you go together with screen printing.

Because of the ink that DTG printers use and the best way that the ink is utilized, the end customer will eventually see the print fade considerably from repeated washing and drying. They print line-by-line – identical to a printer at your house. "We hire display screen printers to run our DTG machines, because it takes a certain set of abilities," says Stoked On Printing's Kevin Oakley. A newer technique that makes use of a digital print head to print designs instantly onto different surfaces, DTG printing is in a speedy development section.

Still, POD companies like Bonfire and TeeSpring supply each DTG and display printing, though there could also be minimum orders. It is value inquiring whether your preferred printer supplies both choices in case your print needs change down the road.

Based just outdoors of Chicago, M&R believes the trade will transfer toward a print-on-demand mannequin. "The similar number of t-shirts shall be bought, but how they're bought and printed will change," said M&R's CEO Danny Sweem. Your pre-treat machine is actually essential for successful DTG printing.

In the printing business, element is the smallest elements of the design, which could embrace fantastic traces, small type, textures or tiny elements. When it involves display printing, it’s at all times about “holding†element. Screen printing comes out aggressive with the one-two punch of saturation and brightness.

Each design has to be bulk printed, limiting the number of customized t-shirts you'll be able to provide in your retailer. The whole course of turns into even more difficult if you don't already have an established customer base. One crucial factor to contemplate when establishing a new business is its impact on our surroundings. The plastisol inks used for display screen printing aren’t biodegradable, and the entire course of requires too much water. Hence, display printing is appropriate for designs having easy geometry, primary shapes, and ordinary symbols. It is tougher to get complicated designs proper each time during printing with this method. Screen printing works finest with standard stable designs which are less advanced.

Welkom bij

Beter HBO

© 2024 Gemaakt door Beter HBO.

Verzorgd door

![]()

Je moet lid zijn van Beter HBO om reacties te kunnen toevoegen!

Wordt lid van Beter HBO